Airplane Design & Build Project

Disaster Drone Relief

My Goal

During my internship with the Innovation Studio at Georgia Tech, I created a design that can deploy first aid kits to disaster areas where immediate help is needed.

Remote Controlled Airplane Design & Build Project

GA Tech Invention Studio Summer Internship project

Capstone Ideation – How to Engineer an Airplane

•This was the first design idea that got me excited to pursue this for my capstone project.

•Airplane design is tricky, and it requires using advanced physics.

•The design require prototyping techniques and understanding how to create a system with electrical controls.

•I had to use Autodesk Fusion 360 and came up with multiple concepts.

•I learned 3D printing techniques using the GA Tech facilities

•I had to learn electrical and mechanical design methods to create a functional design that can fly in a stable manner.

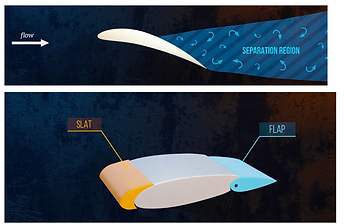

Selected Wing Profile

Creation of MJ0622 (Yes, I named my airplane!)

MJ0622 is Manay Jet and my birthday!

These are the concepts I created; on the right is the final concept.

Design Creation & Fabrication

I created each part in Autodesk Fusion 360 and printed them at the GA Tech Invention Studio. My design had 29 parts and it took 25 hours to print.

Project Storyline

Servomotors and linkage for ailerons and flaps

Servomotors and linkage for ailerons and flaps

I had to position the wings to make sure I get roughly around 5-20deg of angle of attack to keep the electric motor power consumption to a minimum and make the battery last while creating meaningful lift (C_L>1) .

Servomotors and linkage for ailerons and flaps

I had to improvise to get to the final quality build

•Scaled the design up

•Slowed down printer settings and increased resolution

•Changed material from PETG to PLA

Build weight: 850 grams

Take off weight: : 1250 grams

Linkage System and Electronics

TOTAL COST: $82

I used the following design components to operate the plane:

01.

Transmitter 2.5 gHz

02.

Receiver 2.5 gHz

03.

Electronic Speed Control (to control thrust)

04.

2200 mAh 3s LiPo battery

05.

30A 1400 kV brushless motor

06.

6 Servo Motors (2 spares)

07.

Linkages (made from wire hanger)

Final Built

Wireless

My design can be controlled by the wireless transmitter and wireless receiver.

Enhanced Design

I designed it with the intention to deliver emergency medical supplies with eh extra servo motor added to the design.

Control Surfaces

The plane can operate its rudders, elevators, and ailerons.

Problems Encountered:

-

Super glue caused some parts to get damaged

-

Some parts didn’t come out perfectly right the first time. I had to change the receiver to be able to operate the electric motor for take off.

-

Because of the larger size, I had to use a wire hanger and create my own linkages.

GA Tech Invention Studio Internship Experience

I've always been very interested in engineering, but being able to work in the Georgia Tech facilities, learning from the professors and students many new things such as 3D design with Autodesk Fusion, 3D printing, prototyping, electronics, soldering, and design thinking, this was amazing! I learned so much in a short time frame. I also enjoyed spending time with the new friends that I made during my internship.